In September 2022, I wrote about the Windcatcher, a novel wind turbine design seen in the picture below.

Whether Wind Catcher gets built or not, one thing you can say, it is unconventional in design and could like many others follow a trail of good ideas that fail to materialize.

One thing is for sure. Today’s wind turbines just keep on getting bigger. These behemoths stand as tall as 50-storey buildings. Each blade is as long as a football field. The material costs keep mounting up.

Is there a better design in the wings? Enter Airloom. It uses a circular track that can vary in size from metres to kilometres. The towers that track stand 25 metres high and wings replace turbine blades, each 10 metres long.

Referred to as the “craziest ever wind turbine,” the Airloom, see the schematic above, can produce 2.5 Megawatts of power and can be delivered using one standard tractor-trailer. Unlike conventional wind turbines, it doesn’t need a special carrier. It delivers energy at one-third the cost. Manufacturing costs are one-tenth that of conventional wind turbines and deployment is one-quarter the cost.

Airloom can be deployed on land or on the water. Its low profile makes it less of a challenge to those living on coastlines who object to a sea view filled with rotating blades. To see Airloom for real, a prototype can be found in Pine Bluffs, Wyoming. There you can watch the wings traveling around the track. CEO, Neal Rickner, told Fast Company’s Adele Peters last week, “Instead of flying in a circle, that blade is flying across the track and generating a mechanical force just like the blade of a wind turbine.”

An Airloom wind power generation system can operate on land being used to grow crops, graze livestock, or serve other purposes. Unlike conventional wind where each tower needs sufficient space around it to operate, an Airloom installation form factor can be installed in a much smaller space. And instead of looming, windmilling behemoths that you can see from 5 kilometres, an Airloom wind power system would be practically invisible if you were standing less than a kilometre away.

Airloom recently received seed funding from Bill Gates’ Breakthrough Energy Ventures. The money will be used to deliver the first pilot project which is expected to be operational by 2025. The first commercial installations connected to the grid should follow in a couple of years. Airloom hopes to establish partnerships with current wind energy companies and utilities where it feels its novel design will be complimentary. Rickner calls the Airloom, disruption from the inside.

]]>A Novel Wind Turbine

We are increasingly familiar with wind turbines. These immense structures usually found in groups are the windmills of Don Quixote’s worst nightmares. Standing hundreds of metres tall they can dominate a landscape.

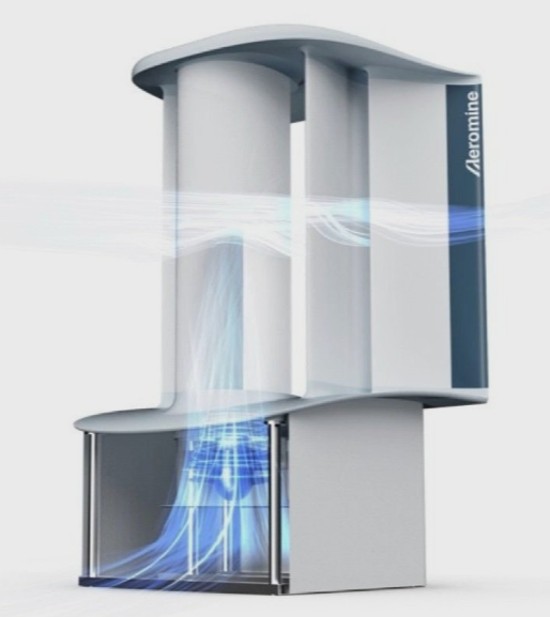

But what if we could design a wind turbine with a much smaller form factor (check out the illustration below and an installation illustrated at the top of this article) that could perform more efficiently and that didn’t disrupt a skyline? That’s what Aeromine Technologies has developed.

The company states that its wind turbine provides 50% more power than solar panels at the same or lower cost. Each wind turbine is small. The moving parts are inside it, unlike conventional wind turbines. The size allows for several to be installed on building rooftops as seen at the top of this article. They can be combined with solar panels. An Aeromine is designed to handle a wide range of weather conditions from little to gale force winds where larger wind turbine technologies would have difficulty operating.

Aeromine is ideal for large commercial buildings with flat roofs. That can include a wide range of structures from multi-unit residential buildings to warehouses, manufacturing facilities, and office buildings. In combination with solar, the two can meet 100% of a facility’s energy needs. It can be part of an off-the-grid solution.

A single Aeromine wind turbine produces the same amount of energy as 16 solar panels. They are easy to install and can operate even in light wind conditions. There are no external rotating blades with each unit producing 5 Kilowatt hours of electricity on average.

Reviving A Bronze Age Technology To Cool Homes

The Bronze Age approximates the period between 3300 and 1200 BCE. It was a period of incredible invention from the smelting and combining of tin and copper to make bronze, as well as the development of alphabets and writing, to the first significant-sized urban-centred civilizations.

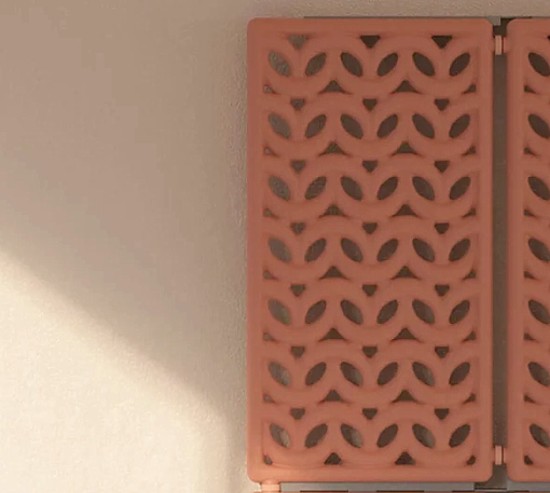

It also was a period in time in the Middle East when terracotta clay containers containing water were used in homes as a source of cool drinking water. At the Holon Institute of Technology, in Israel’s Negev, Yael Issacharov has taken cool water systems found in Palestinian homes called jarrah (which means clay pot in the local Arabic dialect) and turned it into a room cooling solution.

She calls her invention the NAVE. It uses water-filled hollowed terracotta tiles that can be configured for almost any home space. States Issacharov, “since it is a site-specific system, the quantity and size of tiles…depend on the location and size of the space.” She sees it as a perfect solution for arid climates around the world whether the U.S. Southwest or the Sahara Desert.

The NAVE, as seen in the picture below, can be designed as individual wall tiles which can be grouped together to cover a large space, or configured as a terracotta screen or standalone totem pole.

How does it work? The tiny pores in the clay allow the warm water inside to filter through evaporating in contact with the room air. The evaporation cools the water in the NAVE in the same sweating on a hot day cools down our bodies. That in turn lets the NAVE cool the room.

Because each installation and design is customized, a NAVE cooling solution is more expensive initially than conventional air conditioners. But the energy savings once implemented in a home quickly offset the initial outlay. At the same time, the beauty of the design more than compensates, combining both art and artifice.

Issacharov recently received the Gold Medal in Sustainable Living for this novel air conditioner with roots in the Bronze Age at this year’s IDA Design Awards.

]]>Wind Catching Systems is a Norwegian company founded in 2017 that is the developer of these novel wind turbine arrays. Instead of single towers supporting windmill rotors hundreds of metres across, the company has designed arrays that are 324 metres (1,000 feet) tall, containing 126 small wind turbines and generating as much energy as five standalone conventional wind power systems today, Because of their height, Wind Catchers take advantage of higher-altitude wind conditions. Their design provides greater energy capacity and structural flexibility to allow them to operate far from shore in places where conventional turbines dare not go.

In the last week, the company won Fast Company’s Innovation by Design Award in the Sustainability category. Designed specifically to float, each Wind Catcher provides a platform that is easy to maintain, eliminating the need for service boats to provide support. The self-contained array reduces the amount of ocean surface needed per Kilowatt-hour of electricity produced.

The first operational array is expected to go into service in 2024 producing five times more energy than any existing wind turbine. In using smaller rotors and because of its height each Wind Catcher takes advantage of higher wind and rotational speeds.

In June Wind Catching Systems received $10 million USD from General Motors. The investment will help the new company develop its supply chain to mass produce the arrays.

States Ole Heggheim, the company’s CEO, “The turbine system today is a very complicated machine. We’re trying to make it as uncomplicated as possible.” The company hopes to win widespread adoption by offshore wind operators and developers looking to produce electricity at costs that compete with other energy sources and without the need for government subsidies.

Each Wind Catcher is designed to last 50 years without requiring significant maintenance. Compare that to the 30-year average lifespan of conventional wind turbines. And because of the design, Wind Catchers will be easier to manufacture, easier to maintain on location, and easier to recycle at the end of their operational life. One Wind Catcher is rated to produce from 75 to 126 Megawatts of electrical power. That’s enough capacity to power 80,000 homes.

Why did the founders choose to go the multi-turbine route? They looked at the basic design being used in offshore wind production and noted that it became far less efficient when put on a floating platform. That’s why they looked to create something lighter, more flexible, and capable of producing much higher energy yields in a small amount of space. That led to the multi-turbine array that is the Wind Catcher today. In modelling the founders were impressed with the energy yield from a multitude of small turbines.

Their first test was a Wind Catcher mounted on a trimaran. From there they scaled up to the Wind Catcher design seen in the image above. Scaling potential has yet to reach its upper limit with future designs even larger than those to be deployed in 2024.

Beyond the General Motors investment, the company has received backing from Innovation Norway, and Norwegian investors Ferd and North Energy. If all goes well it should have a transformational impact on the offshore wind energy sector.

The first generation of wind turbine blades were made from combinations of balsa wood, glass, carbon fibre, and resins, bound together with glues that proved difficult to remove. Hence these blades have largely ended up in landfill graveyards like the one seen below. Trying to recover materials from them has largely been unsuccessful so they lie in pits looking like row upon row of ghosts.

A Spanish company, Reciclalia, however, has developed new methods for separating the glass and carbon fibre and currently can recycle 1,500 blades per year. Recovered content can’t be used for new turbine blades, but the material is sufficiently strong for automotive, nautical, construction, and consumer product use. The materials recovered can replace thermoset or thermoplastics, engineered plastics, and metals.

Reciclalia’s patented portable Constrictor technology is designed specifically to go to wind farm sites as seen in this Youtube video where the technology chops up dismantled turbine blades and crushes them, minimizing waste and eliminating the need for transportation to an offsite facility.

The company also provides a recycling process that eliminates the resins from the composite materials with less than 10% degradation. The end result is resaleable 100% resin-free materials for different industrial uses including carbon fibre, chopped glass, and glass fibre strands of various thicknesses.

The company was one of four that recently won the first edition of the Retina Eco Award, given by Capgemini and ElPais Retina to organizations and companies providing sustainable and innovative technologies to support global efforts to mitigate climate change and the environment. A jury of scientists and business people picked the company and its technology partner Técnicas Reunidas from 115 candidates who submitted projects covering green energy generation, efficient consumption, smart mobility, and sustainable economics.

Refurbishment of wind turbine blades for current and future farms is expected to produce demand for recycling of an estimated 200,000 blades over the next three decades. In a published 2017 paper produced by researchers from the University of Cambridge, they concluded that the waste produced from used turbine blades will amount to 43.4 million tons by 2050.

A Danish company, Vestas is attempting to address the issue by producing a value chain for the manufacturing and lifecycle of wind turbine blades to achieve zero waste throughout its production processes and supply chain by 2040. Vestas intends to implement circular economic principles in its design, production, service, and end-of-life. In a CNBC article published in 2020, Tommy Rahbek Nielsen, Interim Chief Operations Officer at Vestas, stated, “As the world’s largest supplier of wind energy, Vestas has a responsibility to eliminate waste across its value chain.” He continued, “Wind energy will continue to grow rapidly, therefore the time for a conservative approach is behind us.” The International Energy Agency (IEA) has stated that offshore wind farms will be a $1 trillion business by 2040.

]]>According to Bill Gates and the Breakthrough Energy Sciences (BES) organization founded by the Microsoft billionaire, the U.S. could achieve 70% carbon-free electricity and emissions reductions of 42% by the end of the decade. The cost, $1.5 trillion, $400 billion less than the current COVID rescue plan.

Achieving a renewable energy balance for the U.S. power grid will require investments in clean generation capacity and an enhanced transmission network to support it. Called the Macro Grid, the network will combine high-voltage direct current transmission (HVDC) with conventional AC transmission. Why a combination?

HVDC is more efficient for long-distance transmission. Renewable power generators like wind and solar produce direct current. Using HVDC combined with AC allows for the different regions of the U.S. to complement each other. Some areas like the Western states produce more renewable wind and solar while many Eastern states rely on thermal generated power using coal and natural gas. These power plants are more suited to AC transmission.

BES’s research has focused on four options to connect the country’s renewable resources to customers. It requires significant investments in new wind and solar capacity. Through these investments, the U.S. would be able to reduce annual grid emissions by 850 million tons.

The major challenge that wind and solar present is their variability as energy sources. How do you build an assured energy flow if the wind stops or the sun doesn’t shine? That means “we need to find ways to make the grid more robust to…these kinds of challenges,” states Dhileep Sivam, Vice President of BES.

Improved energy transmission across the U.S. would involve better integration of renewables and an increase in the grid’s resiliency. That’s why finding better ways to transfer electricity across the country is key to making renewable energy increasingly dominant.

In their proposals, BES notes that the energy captured from strong winds and sunny skies in different parts of the country needs to be available to consumers in places where those conditions at the time of generation do not exist. A windy day in Texas should be able to power up homes in California when there is no wind in that state. And a sunny day in California should be able to power a mid-western home in Texas on a day when local winds die down. If such were the case, the problems Texas faced during the recent polar vortex causing coal and natural gas thermal power plants to fail along with breakdowns in local wind turbines, would not have mattered because power would have been delivered to homes and businesses from across the grid originating elsewhere.

The BES proposals, which include upgrades to local AC transmission lines to link up short distances, and HVDC lines to connect resources crossing multiple states would lead to complete decarbonization of the U.S. grid by 2035, meeting the current administration’s targeted goals.

There are jurisdictional challenges to what BES is proposing. In the U.S., every state has sovereignty over energy generation and transmission. Utility companies tend to stay within political boundaries unless they are multi-state energy providers. Therefore local regulatory processes need to be overcome for the BES plan to succeed.

According to BES, if all states that have adopted 2030 clean energy goals were to meet them, the cost of upgrades would be $360 billion. The emissions reduction, however, would amount to a mere 6%, a far cry from the national target or the one proposed by BES above.

What’s missing from the BES plan. There is no discussion about energy storage and how adding battery capacity could impact the grid. Nor is there any mention of green hydrogen.

BES has made their model open source to allow anyone in the field to comment and contribute to the plan. Plans are afoot to look at Europe and other geographies.

]]>

Aruba is a desert island to the north of Venezuela in the Caribbean Sea. It has no natural water sources and very little rain, although yesterday two passing showers betrayed that fact. There is a constant wind that blows here without respite. It is the Trade Winds that brought European explorers to the Americas in the 15th and 16th centuries. The sun shines on this island almost every day, probably more than almost any other place on the planet.

Knowing these latter two facts would make you think, what an ideal place to use renewable solar and wind. But surprisingly, there is little evidence of either here. The island, being close to Venezuela imports that country’s heavy oil which is refined and used for power generation and transportation. Ther are early signs of a growing utility-based renewable energy infrastructure, and many homes have solar water heaters and photovoltaic panels. But this island, if any, should be totally powered by renewable sources.

There is one significant challenge and that is the lack of fresh water. Aruba gets all of its fresh water from the Caribbean through a desalination plant that serves the island’s permanent inhabitants and the burgeoning tourism trade.

The choice of coming here was to give both of us a chance to be outside as winter descends on Toronto, bringing grey skies, short days with little sunlight, the cold, and ice and snow. For my wife who suffered a concussion a year ago when she fell, being able to walk without fear of falling is a blessing. For me, with a pending knee replacement in the offing, the ability to not have to deal with the ice and snow means I can get around although I am using brace and cane to achieve this. My surgery is scheduled in the spring after the winter snow has passed.

So if you are a regular reader of this blog, I will be firing on all cylinders in a week’s time. In the meantime, go to the home page of the site to follow the Twitter feed which I regularly update even while traveling. It can be found on the right-hand side of the site. And if I come across a new video to share you will find it as well farther down on the right side.

I want to thank the more than 50,000 subscribers who regularly receive this content, and the millions of page views that readers have given to this site. After more than nine years at this task, and nearly 2,900 postings, your continued interest inspires me to tackle the progress of science, technology, and environmental policy and actions in this 21st century.

]]>

Called Wake Adapt, this is technology mimicking nature. The prime example of wake adaptation can be found in the V formations used by geese and other bird species. As the birds flap their wings a rotating vortex of air flows from each wingtip. The air immediately behind the lead bird in the V is pushed downward while the air to the side of each wing gets pushed upward. A bird flying immediately behind would be negatively impacted, but a bird flying just to the side would gain the benefit of the free uplift and use less energy in flight.

Wind farms on the water are also in formation, not necessarily Vs but often in parallel like the image seen below. Wake Adapt software, like the birds in V formations, produces wake-steering to ensure a more powerful flow of air follows the “lead” turbine. The software adjusts the yaw of individual wind turbines trailing the lead to maximize the energy yield from increased airflow over the vanes.

How much of an increase? Siemens states that a wind park’s performance in terms of energy production can increase by 1% through the application of the software, and reduces the negative wake effect by as much as 10% across the entire wind farm.

How does that translate into electrical power for heating, lighting, and cooling? Using statistics from 2017 when wind power capacity reached 18.8 Gigawatts, a 1% increase equalled 188,000 kilowatt/hours which was sufficient to power 6,000 more U.S. homes annually than without the software.

Siemens is currently installing the software on Direct Drive and Geared G4 series wind turbines and can retrofit all existing inventory of deployed offshore windfarms to use it. The patent is held by The Netherlands Organization for Applied Scientific Research, who partnered with Siemens in Wake Adapt’s development.

States Morten Pilgaard Rasmussen, Head of Offshore Technology at Siemens Gamesa, “The Wake Adapt feature is about proactive problem-solving. Instead of letting the wind and wake fully dictate how much energy we can capture, we safely direct the wake, and its unfavorable effects, away from our machines across the entire power plant. Through digitalization, we can produce more energy from the same turbines, benefiting our customers, ratepayers, and society overall.”

Wake Adapt is customizable to individual offshore wind turbine installations, is remotely activated and automatically adjusts the headings of individual turbines to produce more powerful and undisrupted winds for trailing turbines. Capturing more of the latent energy from the wind means turbine efficiency improvements at the individual unit level as well as for the entire wind farm installation.

As the largest offshore wind turbine producer in the world, Siemens recognizes the industry potential for growth in the face of creating low-carbon energy alternatives to coal, other fossil-fuel, and nuclear power. The annualized industry growth rate is expected to be 13% and to continue at that pace through 2025.

In the latest Navigant Research study entitled “Country Forecasts for Distributed Energy Storage,” it cites solar and wind power as the primary growth drivers for DESS indicating a twentyfold increase in usage in 26 countries by 2028. Ricardo F. Rodriguez, one of Navigant’s research analysts argues that DESS represents flexibility in energy generation infrastructure deployment and “limits the need for peak capacity resources.”

Generating continuous electricity to match demand requirements has always been the most significant detractor for the use of intermittent renewable energy resources. Particularly, in countries where the bulk of electricity is distributed over a ubiquitous grid, utility companies to ensure predictable, continuous power build to exceed peak demand requirements. Whether the power comes from thermal power plants burning coal, or natural gas, or from solar and wind farms, exceeding peak demand is an industry sacred cow. That surplus power generation, produced in off-peak periods can find a home in DESS.

You are probably thinking that DESS comes in the form of large batteries that can discharge stored energy when needed. But energy storage comes in many different forms, not just chemical batteries. For example, surplus power can pump water uphill into reservoirs where it can be released as needed or can create compressed air storage which when released can drive turbines connected to generators.

The real strength of DESS is in its ability to help energy companies transition from traditional thermal-power generation to renewables. DESS smooths out the supply of electricity from intermittent energy sources of which the sun and wind are two. And DESS can discharge power quickly unlike reserve fossil-fuel burning thermal power stations which require a considerably longer ramp-up. DESS also works best in remote areas away from a ubiquitous transmission grid where power disruptions are more frequent. In these more isolated regions, a microgrid distribution system with DESS backup can prove to be an ideal solution.

The Union of Concerned Scientists, in a 2015 publication, noted that the United States had 23 Gigawatts of storage capacity equal to 38 typical coal-fired power plants. At that time pumped hydroelectric storage represented 96% of total capacity. But growth in DESS is likely not to come from hydroelectric pumped storage but rather from alternative solutions such as large-scale chemical battery vaults like the ones seen to the right in the illustration below.

Examples of DESS in practice are growing. There is the Tesla-installed 100 Megawatt lithium-ion battery system recently installed in Hornsdale, South Australia. Billed as the world’s largest lithium-ion storage system, it is one of a number of projects slated for completion in Australia by 2021 and includes a 900-Megawatt battery from Neoen SA, a 270-Megawatt installation built by Total Eren SA, and a 140-Megawatt battery from EPS Energy.

Flow batteries are among the mix in energy storage solutions. These giant storage tanks of liquid electrolytes can provide a lower-cost solution than lithium-ion stacked battery technologies such as the system Tesla installed at Hornsdale.

More recently I have written about modular cryogenic energy storage systems such as the CRYOBattery providing power to 200,000 homes in the United Kingdom. And even funkier is kinetic storage devices like flywheels which, deployed in a farm of these devices, is currently providing 20-Megawatts of power at the Stephentown Flywheel Energy Storage Plant in New York State.

The biggest impediment to wholesale DESS deployment will be the reluctance of energy providers to adopt the technology with a pre-existing infrastructure of sunken costs into fossil-fuel-based electricity production. Mitigating climate change, however, will be the driving force for DESS growth with governments around the world seeing the value of storage associated with intermittent renewable energy as the new paradigm for power generation.

Energy storage will not come cheap. The necessity, however, to address carbon emissions, and the limitations on hydroelectric renewable power capacity with fewer sites available, are among the factors behind Navigant’s forecast of a 2,000% growth.

Postscript

A reader of this blog posting, Bob Meinetz, suggested that Navigant’s forecast is, in his words, “far too conservative.” He refers to Lazard, and Deutsche Bank forecasts of anywhere from 12,000 to 20,000%, and GreenTech Media reporting an increase of more than 70,000%.

]]>Maersk along with other maritime shipping companies are seeking ways to reduce their carbon footprints. One way has involved reintroducing wind power into maritime transportation. Most of us, however, think of wind power and traditional canvas sails. Norsepower, however, has experimented with an alternative dredged up from the past, a failed 1926 invention, a rotating cylinder that uses its motion to create a push phenomenon similar to the wind hitting sails. In this case, however, the airstream created comes from backspin, just like a spinning baseball released by a pitcher creates lift changing the flight of the ball.

Norsepower, the builder of the rotor sails has installed them on three ships so far. In the Pelican project, they partnered with Maersk Tankers, Energy Technologies Institute (ETI), and Shell International Trading and Shipping Company. Independent oversight and performance analysis was carried out by Lloyd’s Register’s Ship Performance Group. The partners plan to publish detailed results of the one-year pilot project.

Tommy Thomassen, CTO of Maersk Tankers when interviewed described the positive outcome of the one-year test noting optimal usability, safety, and performance under all conditions the Pelican faced. The company is looking for ways to reduce overall greenhouse gas (GHG) emissions and Thomassen sees wind technology as a potential breakthrough. Maersk has set a fleet emission reduction target of 30% by 2021, and 60% reduction from a 2008 baseline by 2030. The plan is to continue operating the Pelican with rotor sails and install the technology on other ships in the fleet.

Shipping is responsible for between 2 and 3% of GHGs, and with 80% of global trade traveling by sea, the industry is working on getting to a state of carbon neutrality by 2050. Maersk wants to be zero-emission in its operations by that date. To get there the company is experimenting with new ship designs, carbon-neutral fuels, rechargeable, and continuous-charge electric propulsion systems, and, of course, wind power. Total investment to achieve carbon neutrality so far has amounted to $1 billion USD. The company has reached out to researchers, academics, technology inventors, investors, cargo owners, and governments seeking co-development and sponsorship of sustainable solutions that eliminate traditional fossil fuels from maritime shipping. The company describes climate change as “one of the most important issues in the world.”

The AEM is installed in a modular unit called the Electrolyser 2.0, (EL2). Each unit takes tap or rainwater and splits it into oxygen and hydrogen. The latter is then pressurized and stored to supplement electricity generated by intermittent renewable sources. Enapter’s latest showcase is a residential installation at the home of Arno Tilsner, a magazine publisher who has been living off-the-grid since 2012. Tilsner uses solar panels on the roof of his home to power up his electric vehicles. The acquisition of the EL2 is Tilsner’s use case validation of the technology and a showcase which he is writing about weekly in his magazine. The on-site energy system is equipped with 5 Kwh solar panels which generate electricity throughout the day. Excess energy produces 500 liters of hydrogen per hour which can then be converted back into electricity through a fuel cell.

Tilsner calls hydrogen “the stuff of the century, the universal building block of the post-coal-oil-gas era.” He is not wrong in making this claim. The hydrogen problem, however, is seen as multi-faceted. First there is the perception of its volatility. Hydrogen was used by the Hindenburg, the German zeppelin that caught fire and burned back in 1937. Liquid hydrogen fuel combined with liquid oxygen powered the Saturn 5 rocket during the Apollo Program.

And then there is the challenge of producing hydrogen gas economically. To date, it takes more energy input to produce hydrogen than the energy gained from the harvested gas. Electrolysis from water has always been seen as cost-prohibitive when compared to harvesting the gas from fossil fuel sources. But the problem of hydrogen extraction from fossil fuels ends up defeating the whole idea of the gas as a green fuel.

The El2 changes the economics of hydrogen generation from water. It is stackable. Starting with a single 500-liter module it can be expanded to a stack that can handle up to 10,000 liters per hour. As Tilsner describes his experience to readers of his magazine, he may begin to convince more potential customers to adopt the technology. That is already happening with installations in 26 countries around the world providing grid-independent energy storage in remote areas, seasonal energy storage in extreme environments, industrial on-site hydrogen generation, backup power for telecom providers, and hydrogen fuel for mobile applications.

]]>